- SaniCoat®

-

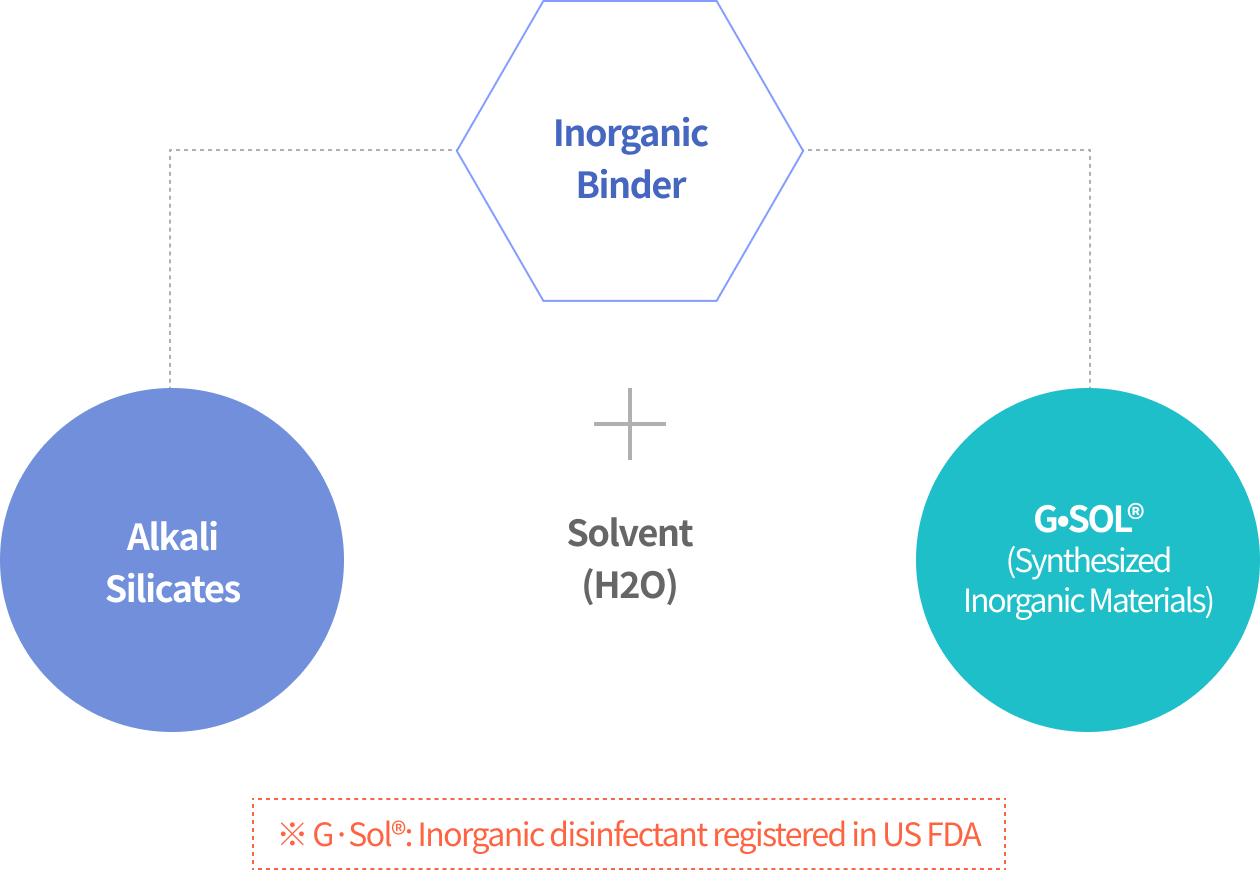

Eco-Friendly Ultra-Hydrophilic Inorganic Coating Materials

with Anti-Corrosion and Anti-Microorganism Functions

- Super Hydrophilic Anti-Fouling

-

Anti-Fouling &

Easy Cleaning

- Excellent Corrosion Resistance Anti-Corrosion

- Anti-corrosion effect in acid & alkali solution as well as sea water

- Powerful Sanitizing Anti-Biofouling

- Using Inorganic disinfectant Material G·SOL® registered By US FDA

The features of SaniCoat®

| Item | Test result* | Features |

|---|---|---|

| Contact angle | About 10°(Ultra-hydrophilic) | Anti-Fouling & Easy Cleaning |

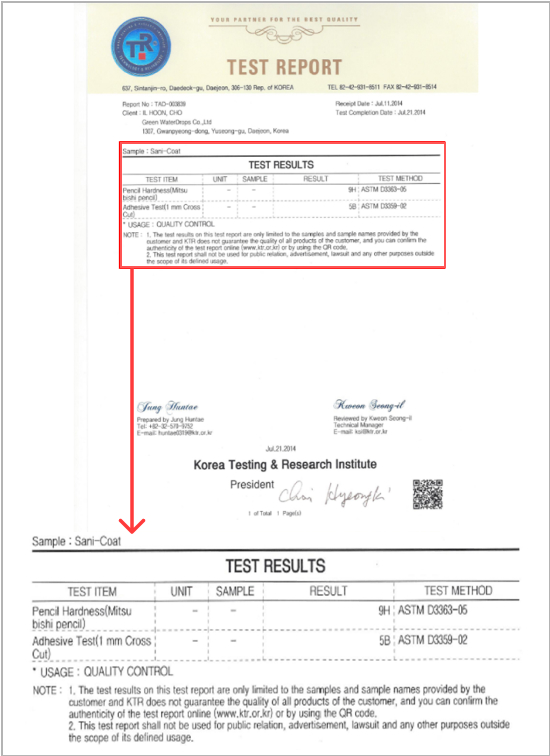

| Surface hardness | Over 9H(Pencil hardness) | Resistant to surface impact due to high hardness |

| Adherence | Over 5B | Excellent adhesion and long-term maintenance |

| Corrosion resistance |

No surface corrosion due to acid (H2SO4), alkali(NaOH), sea water (NaCl), etc. | Anti-corrosion effect in acid & alkali solution as well as sea water |

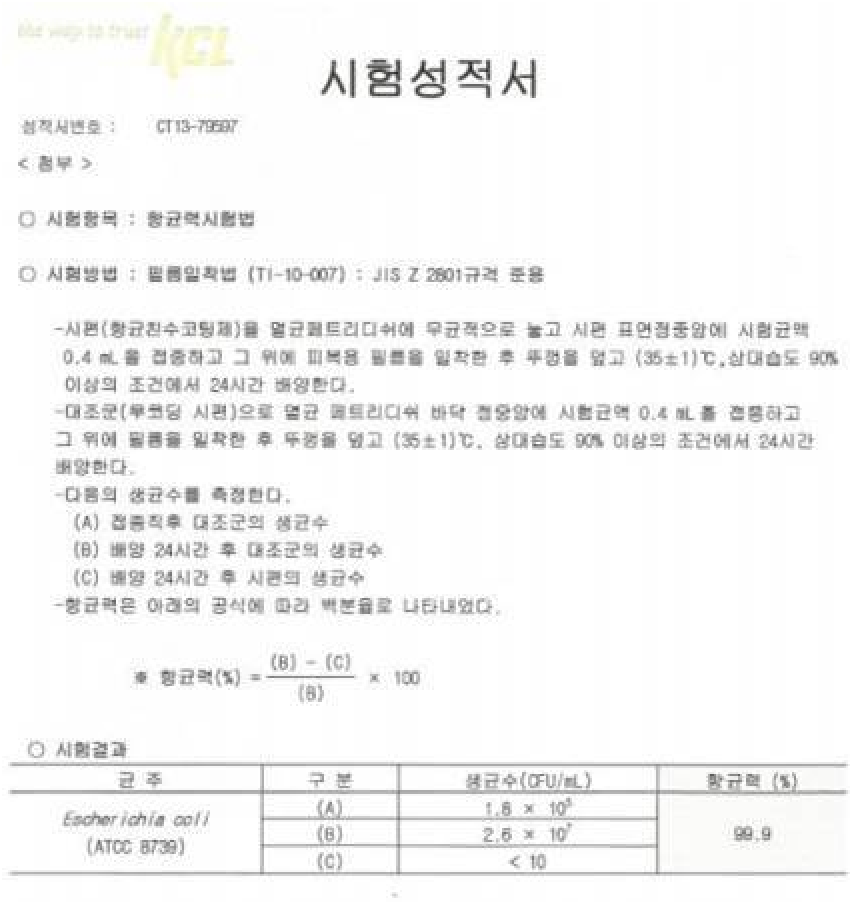

| Antibacterial | Over 99.9% (Escherichia Coli, etc.) | Various bacteria and viruses can be removed by formulation of inorganic sanitizing material registered by US FDA as a disinfectant(Anti-biofouling) |

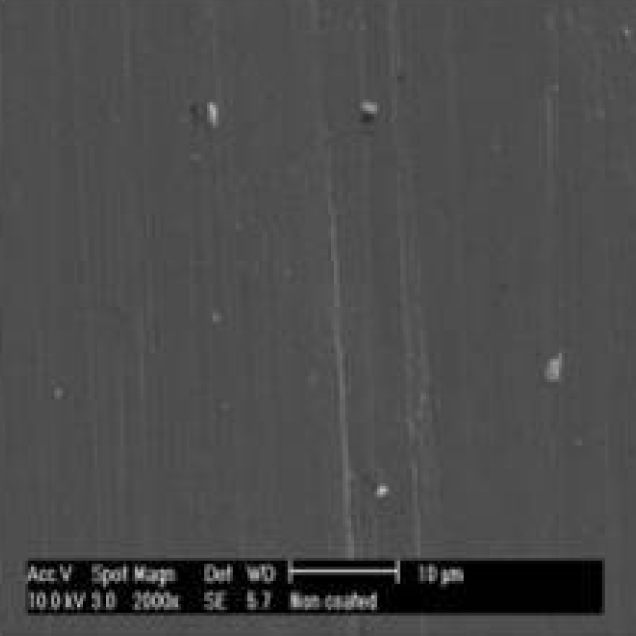

Physical and chemical properties 1. High Hardness

Uniformly Coated/Over 9H (hardness test result)/Over 5B (adhesive test result)

Before Coating (SUS)

Before Coating (SUS)

After Coating (SUS)

After Coating (SUS)

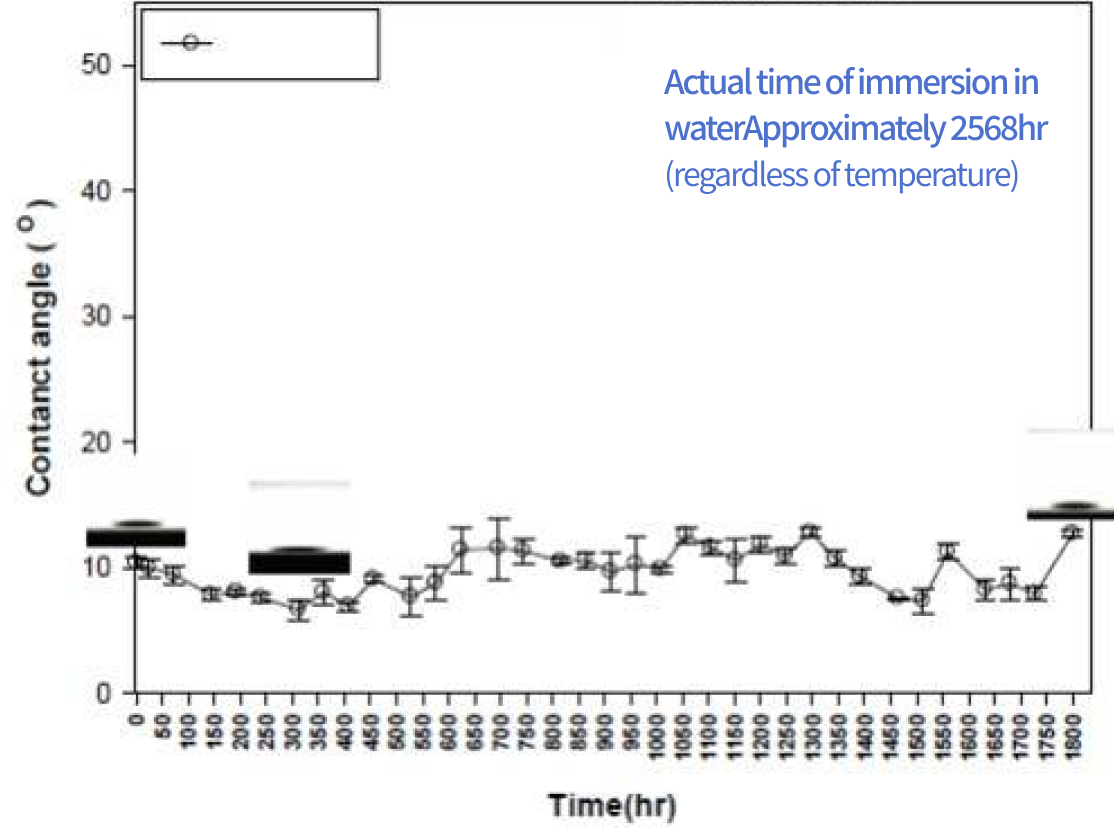

Physical and chemical properties 2. Super Hydrophilic

Contact angle: about 10o/No water drop

Contact angle : 52.3 °

Contact angle : 52.3 °(Hydrophobic)

Contact angle : 10.3 °

Contact angle : 10.3 ° (Ultra Hydrophilic)

| Sort | Contact Angle |

|---|---|

| Water Repellent | Over 90° |

| Hydrophobic | 30° ~ 90° |

| Hydrophilic | Under 30° |

| Ultra Hydrophilic | Under 20° |

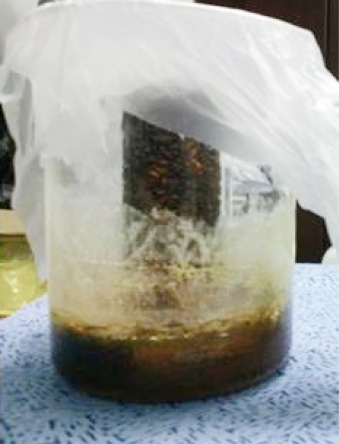

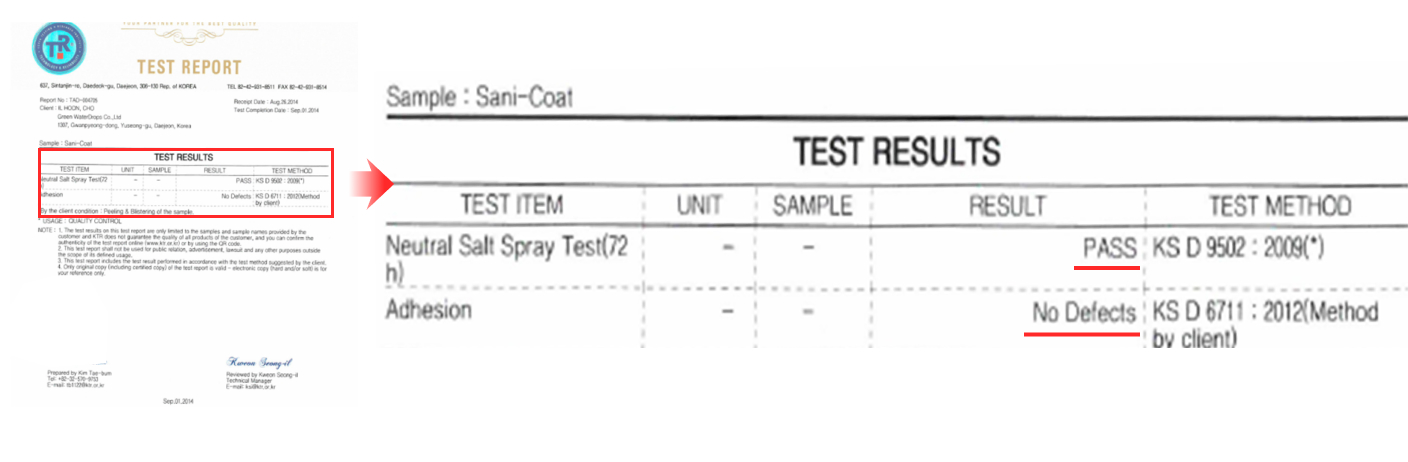

Physical and chemical properties 3. Corrosion Resistance

Excellent Corrosion Resistance against Acid and Base

10% NaDCC(Sodium Dichloroisocyanurate) – 24h

-

Non-coated SUS

Non-coated SUS

-

Coated SUS

Coated SUS

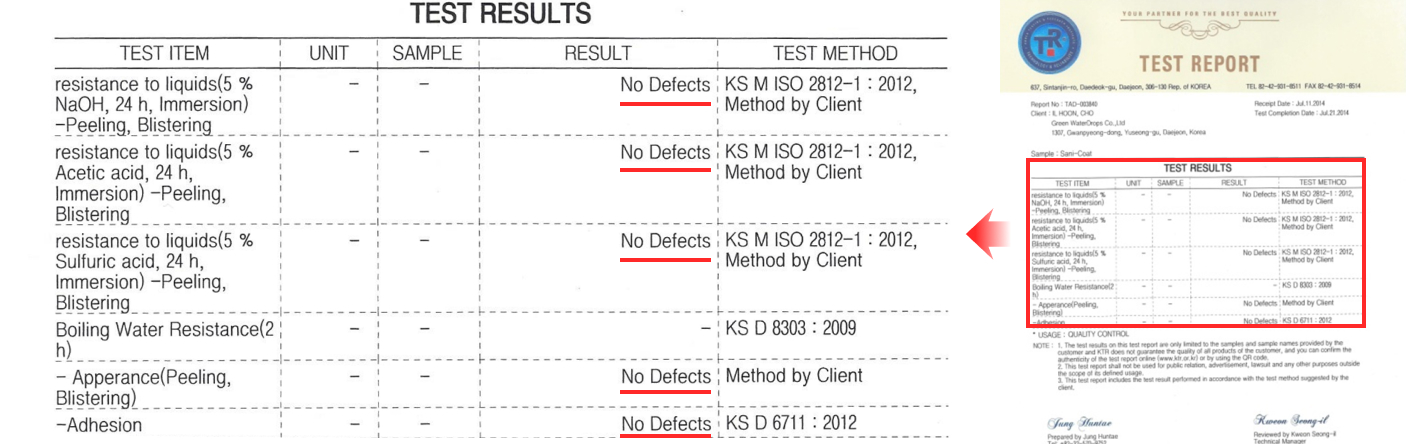

Corrosion resistance test results such as peeling after liquid resistance,

blistering, boiling water resistance, adhesion, etc.

- Corrosion resistance test results

-

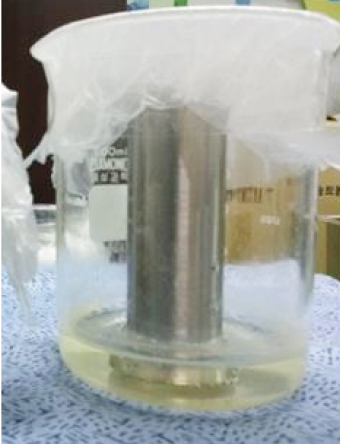

No corrosion in NaCl Solution (Sea Water)

-

Non-coated SUS

Non-coated SUS

-

Coated SUS

Coated SUS

- Corrosion resistance test results

-

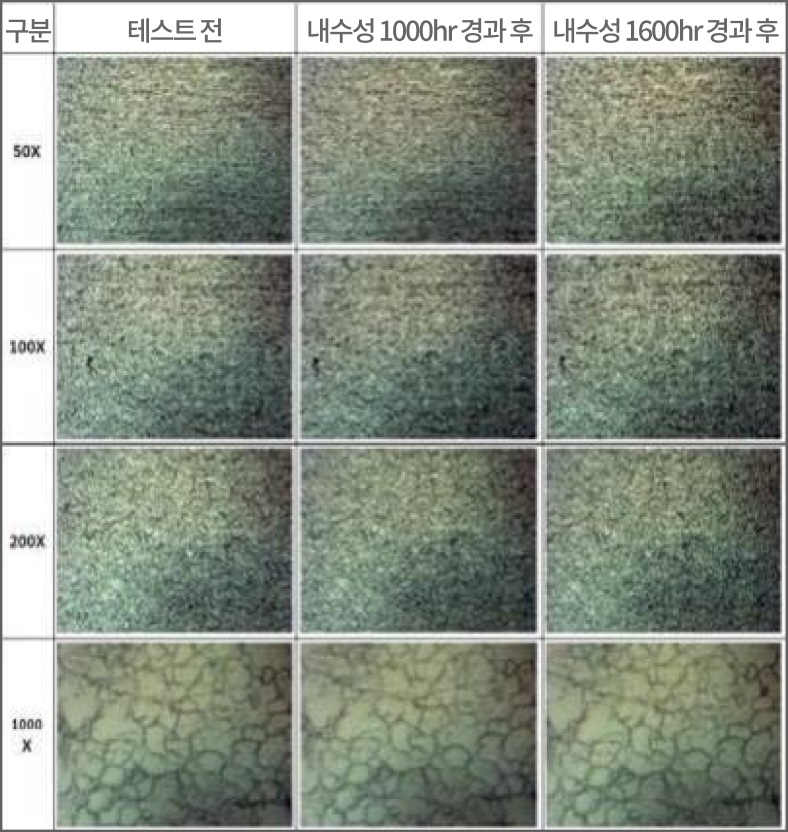

Physical and chemical properties 4.Excellent Cleanable

Easily remove contaminants using only waterAnti-Fouling & Anti-Scaling

- Test of Removal Contaminants by Coated with SaniCoat® on SUS Sample

-

- Super Hydropilic - Simply rinse with water to remove contaminants

-

Bactericidal Efficacy Tests

Test bacteria : Escherichia Coli

Efficacy 99.9%(FITI Testing and Research Institute, South Korea)

Comparisons of Technical Data of SaniCoat® with Others

| 구분 | SaniCoat® | Fluoropolymer | Enamel | Organic/Inorganic Hybrid Ceramicnent |

Remark |

|---|---|---|---|---|---|

| Contact Angle | About 10° (Ultra-Hydrophilic) |

Over 90° (Water Repellent) |

under 80° (Hydrophobic) |

under 90° (Hydrophobic) |

|

| Sanitizing Power | Over 99.9% | No | No | No | |

| Durability | No changes for long time - Long lasting | Gloss and color change | No changes with time, but rust occurs due to cracks | No changes with time, but gloss and color may change | |

| Smoothness | Excellent | Good | Poor | Fair | |

| Washability | Easy wash with water | Need special solvent to wash | Need solvent to wash | Need solvent to wash | |

| Chemical Resistance |

No changes by strong acid and alkali | Weak chemical resistance | No changes by acid and alkali | Vulnerable to alkali | |

| Sintering Temperature |

~ 250°C | 250 ~ 280°C | 650 ~ 900°C | 180 ~ 250°C | |

| Hardness (Pencil Hardness) |

Over 9H | Over 1H | Over 9H | Below 1H |

Application Fields of SaniCoat®

- Heat Exchanger

- Scrubber

-

Marine Structures

(Pipes & Tanks) -

Anticorrosion &

antifouling treatment -

Pharmaceutical

facility - Evaporator

- Water purifier

- Washing machine

- Sanitary ware

- Can

- Water tank